Cold Room Panels

Cold storage room panels are specialized panels used in the construction of cold storage facilities such as walk-in refrigerators, freezers, and cold rooms. These panels are designed to provide effective insulation and temperature control to preserve perishable goods, food products, pharmaceuticals, and other temperature-sensitive items.

Insulation: Cold storage room panels are typically constructed with a core material that provides excellent thermal insulation properties. Common core materials include expanded polystyrene (EPS), polyurethane (PU), or polyisocyanurate (PIR) foam. These materials help maintain the desired temperature inside the storage facility by minimizing heat transfer.

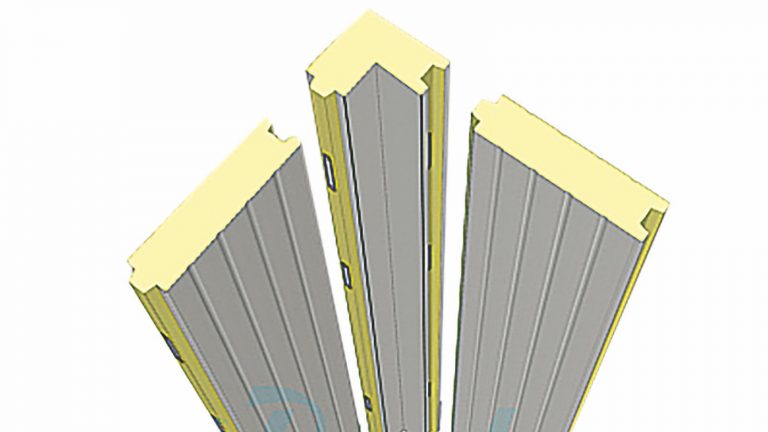

Panel Structure: The panels consist of an insulated core sandwiched between two facing materials. The facing materials are often made of durable materials like galvanized steel, stainless steel, or aluminum. These materials provide structural strength, durability, and resistance to corrosion, making the panels suitable for use in various environments.

Modular Design: Cold storage room panels typically feature a modular design, allowing for easy assembly and installation. The panels come in standard sizes and can be quickly assembled on-site to create the desired storage space. This modular construction also facilitates flexibility in design and allows for customization according to specific requirements.

Tongue-and-Groove Joints: To ensure a tight and secure fit, cold storage room panels are designed with tongue-and-groove joints. These interlocking joints help minimize air leakage and maintain the integrity of the insulation barrier, thus maximizing energy efficiency.

Vapour Barrier: Proper moisture management is essential in cold storage facilities to prevent condensation and maintain product quality. Cold storage room panels are often equipped with a vapor barrier layer to prevent moisture ingress and to ensure a dry and controlled environment inside the storage area.

Temperature Control: Cold storage room panels are engineered to provide effective temperature control, maintaining consistent and stable temperatures within the storage space. This is crucial for preserving the freshness and quality of perishable goods over extended periods.

Hygiene and Cleanliness: In industries such as food storage and pharmaceuticals, maintaining hygiene and cleanliness is paramount. Cold storage room panels are designed to meet stringent hygiene standards and are easy to clean and sanitize, reducing the risk of contamination.

Energy Efficiency: Insulated cold storage room panels contribute to energy efficiency by minimizing heat transfer and reducing the load on refrigeration systems. This can lead to lower energy consumption and operating costs over time.

Overall, cold storage room panels play a critical role in the construction of temperature-controlled storage facilities, providing reliable insulation, structural integrity, and temperature control to preserve sensitive products effectively.

What is our difference?

Contact us to get a quote and a drawing for your projects.